Shoemaking Course Content

All modules and lessons included in the Shoemaking & Patternmaking Course

Part 1: Pattern Making - Derby Model

1.1. Wrapping the shoe last

1.2. Establishing the main points and lines of the shoe last

1.3. Drawing the design lines of the model

1.4. Transferring shoe last shells in 2D

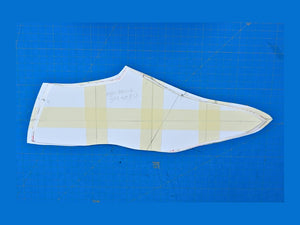

1.5. Obtaining the Mean Forme

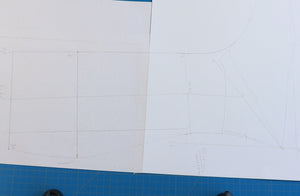

1.6. Placing the Mean Forme in the xOy coordinate system

1.7. Transferring the design lines

1.8.1. Technical drawing - Part 1

1.8.2. Technical drawing - Part 2

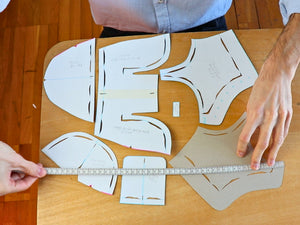

1.9. Extracting the patterns from technical drawing

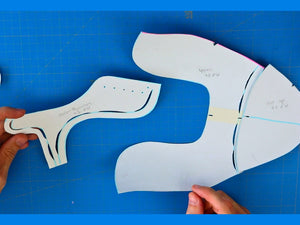

1.10. Getting the final patterns on cardboard

Part 2: Pattern Making - Oxford Model

2.1. Efficient Use of a Pre-Existing Mean Forme

2.2. Placing the Mean Form in the xOy coordinate system

2.3. Establishing the main lines of the model

2.4. Drawing the design lines of the model

2.5. Technical drawing

2.6. Extracting the patterns from technical drawing

2.7. Getting the final patterns on cardboard

Part 3: Pattern Making - Loafer Model

3.1. Wrapping the shoe last

3.2. Establishing the main points and lines of the shoe last

3.3. Drawing the design lines of the model

3.4. Transferring shoe last shells in 2D

3.5.1. Technical drawing Loafer - Part. 1

3.5.2. Technical drawing Loafer - Part. 2

3.6. Extracting the patterns from technical drawing

3.7. Getting the final patterns on cardboard

Part 4: Pattern Making - Ballerina Shoe Model

4.1. Wrapping the shoe last

4.2. Establish the main points and lines

4.3. Transferring shoe last shells in 2D

4.4. Technical drawing

4.5. Extracting the upper and lining patterns from technical drawing

4.6. Creating and extracting the reinforcements patterns

4.7. Getting the final patterns on cardboard

Part 5: Pattern Making - High Heels Shoes (Court Heels)

5.1. Wrapping the shoe last

5.2. Establish the main points and lines

5.3. Transferring shoe last shells in 2D

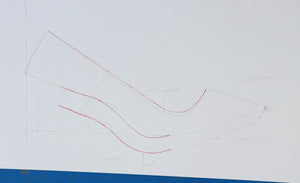

5.4. Obtaining the Mean Forme

5.5. Placing the Mean Forme in the xOy axes system

5.6. Technical drawing

5.7. Getting the upper and lining patterns from technical drawing

5.8. Creating and getting the reinforcements patterns

5.9. Creating the heel pattern

5.10. Getting the final patterns on cardboard

Part 6: Pattern Making - Sandals

6.1. Wrapping shoe last

6.2. Establish the main points and lines

6.3. Drawing the design lines of the model

6.4. Transferring the pieces in 2D

6.5. Technical Drawing

6.6. Extracting the upper patterns from the technical drawing

6.7. Creating and extracting the linings

6.8. Creating and extracting the reinforcements (optional)

6.9. Creating the bottom patterns

6.10. Creating the heel pattern

6.11. Getting the final patterns on cardboard

Part 7: Pattern Making - Sneakers

7.1. Wrapping the shoe last

7.2. Establishing the main and design lines on the shoe last

7.3. Transferring shoe last shells in 2D

7.4. Obtaining the Mean Forme

7.5. Placing the Mean Form in the xOy coordinate system

7.6. Transferring the design lines

7.7. Technical drawing

7.8. Extracting the upper patterns from the technical drawing

7.9. Creating and extracting the linings

7.10. Creating and extracting the fillings and reinforcements

7.11. Getting the final patterns on cardboard

Part 8: Pattern Making - Ankle Boots

8.1. Wrapping shoe last

8.2. Establishing the main and design lines on the shoe last

8.3. Transferring shoe last shells in 2D

8.4. Obtaining the Mean Forme

8.5. Placing the Mean Form in the xOy coordinate system

8.6. Transferring the design lines

8.7.1. Technical drawing - Part. 1

8.7.2. Technical drawing - Part. 2

8.8. Extracting the patterns from technical drawing

8.9. Getting the final patterns on cardboard

Part 9: Pattern Making - Calf High Boots

9.1. Placing the Mean Form in the xOy coordinate system

9.2.1. Establishing the main lines of the model - part 1

9.2.2 Establishing the main lines of the model - part 2

9.3. Drawing the design lines of the model

9.4. Technical drawing

9.5. Extracting the upper patterns from the technical drawing

9.6.1. Creating and extracting the linings - part 1

9.6.2. Creating and extracting the linings - part 2

9.7. Creating and extracting the reinforcements

9.8. Getting the final patterns on cardboard

Part 10: Grading / Scaling

Download the Grading Table

10.1.1. Grading on the mean forme - part. 1

10.1.2. Grading on the mean forme - part. 2

10.2. Grading on the technical drawing

Part 11: Material Consumption

11.1. Estimating Material Consumption

Shoemaking Equipment and Tools You Will Need

1 - Main Tools Commonly Used in Shoemaking

2 - Main Materials Commonly Used in Shoemaking

3 - Main Shoemaking Adhesives-Glues

4 - Basics of Shoemaking Stitching

❓Where to Find Shoemaking Supplies

Part 12: Cutting and Skiving Leather

12.1.1. Basics of Leather Cutting

12.1.2. Basics of Lining Cutting

12.1.3. Basics of Reinforcements Cutting

12.2. Basics of Edge Skiving

Part 13: Shoe Making Process - Derby Model

13.1. Overview of the Cut Pieces

13.2. Overview of the Skived Pieces

13.3.1. Assembling and Sewing the Uppers - Part 1

13.3.2. Assembling and Sewing the Uppers - Part 2

13.4.1. Lasting the Uppers - Part 1

13.4.2. Lasting the Uppers - Part 2

13.4.3. Lasting the Uppers - Part 3

13.5.1. Sole construction - Part 1

13.5.2. Sole construction - Part 2

13.6.1. Heel construction - Part 1

13.6.2. Heel construction - Part 2

13.7. Heel and Sole Edge Finishing

13.8. Shoe Last Removal

13.9. Insole Cover Application

13.10. Finishing

Part 14: Shoe Making Process - Oxford Model

14.1. Overview of the Cut Pieces

14.2. Overview of the Skived Pieces

14.3.1. Assembling and Sewing the Uppers - Part 1

14.3.2. Assembling and Sewing the Uppers - Part 2

14.3.3. Assembling and Sewing the Uppers - Part 3

14.4. Applying pre-made Rubber Sole

Part 15: Shoe Making Process - Loafer Model

15.1. Overview of the Cut Pieces

15.2. Overview of the Skived Pieces

15.3.1. Assembling and Sewing the Uppers - Part 1

15.3.2. Assembling and Sewing the Uppers - Part 2

15.4. Creating the Insole and Sole Pattern

15.5.1. Lasting the Uppers - Part 1

15.5.2. Lasting the Uppers - Part 2

15.6.1. Sole construction - Part 1

15.6.2. Sole construction - Part 2

15.6.3. Sole construction - Part 3

15.7. Attaching the Sole

15.8. Insole Cover Application

Part 16: Shoe Making Process - Ballerina Model

16.1. Overview of the Cut Pieces

16.2. Overview of the Skived Pieces

16.3. Assembling and Sewing the Uppers

16.4. Creating the insole pattern

16.5.1. Lasting the Uppers - Part 1

16.5.2. Lasting the Uppers - Part 2

16.6. Sole Application

16.7. Insole Cover Application

Part 17: Shoe Making Process - High Heels (Court)

17.1. Overview of the Cut Pieces

17.2. Overview of the Skived Pieces

17.3. Assembling and Sewing the Uppers

17.4. Heel Cover Application

17.5. Creating the Sole Pattern

17.6.1. Lasting the Uppers - Part 1

17.6.2. Lasting the Uppers - Part 2

17.7. Sole Making

17.8. Sole Application

17.9. Heel Application

17.10. Insole Cover Application

Part 18: Shoe Making Process - Sandals

18.1. Overview of the Cut Pieces

18.2. Assembling and Sewing the Uppers

18.3. Preparing the bottoms

18.4. Lasting the uppers

18.5. Sole Application

18.6. Heel Application

18.7. Insole Cover Application

Part 19: Shoe Making Process - Sneakers

19.1. Overview of the Cut Pieces

19.2. Overview of the Skived Pieces

19.3.1. Assembling and Sewing the Uppers part 1

19.3.2. Assembling and Sewing the Uppers part 2

19.4. Creating the insole pattern

19.5.1. Lasting the uppers - Part 1

19.5.2. Lasting the uppers - Part 2

19.6. Sole application

Stitching the sole: demonstration

19.7. Insole Cover Application

Part 20: Shoe Making Process - Ankle Boots

Recommended Materials for Ankle Boot Uppers

20.1.1. Assembling and Sewing the Uppers - part 1

20.1.2. Assembling and Sewing the Uppers - part 2

20.2. Creating the insole

20.3.1. Lasting the uppers - Part 1

20.3.2. Lasting the uppers - Part 2

20.4. Midsole application

20.5. Midsole Hand-Stitching

20.6. Sole application and Hand-Stitching

Part 21: Shoe Making Process - Calf Boots

21.1. Overview of the Cut Pieces

21.2. Overview of the Skived Pieces

21.3.1. Assembling and Sewing the Uppers - part 1

21.3.2. Assembling and Sewing the Uppers - part 2

21.3.3. Assembling and Sewing the Uppers - part 3

21.3.4. Assembling and Sewing the Uppers - part 4

21.4.1. Lasting the uppers - Part 1

21.4.2. Lasting the uppers - Part 2

21.4.3. Lasting the uppers - Part 3

21.5. Sole application

21.6. Insole Cover Application

Dyed Oxford - Shoemaking Course

Oxford Patterns

1. Main materials needed

2. Overview of the patterns

3. Overview of the Cut Pieces

4. Overview of the Skived Pieces

5. Dyeing the Pieces

6. Assembling and Sewing the Uppers

7. Lasting the Uppers

8. Adding Shading Effects

9. Sole construction

10. Heel construction

11. Edge Finishing – Smoothing Heel and Sole

12. Edge Finishing – Dyeing and Waxing Heel and Sole

13. Finishing the Bottom of the Sole

14. Finishing the Uppers

15. Shoe Last Removal

16. Insole Cover Application

High Top Sneakers - Shoemaking Course

High Top Sneakers Patterns

1. Main materials needed

2. Overview of the patterns

3. Overview of the Cut Pieces

4. Overview of the Skived Pieces

5. Dyeing the Pieces

6. Assembling and Sewing the Uppers

7. Creating the insole pattern

8. Lasting the Uppers

9. Adding Shading Effects

10. Sole application

11. Sole stitching

12. Insole Cover Application

Moc Boots - Shoemaking Course

Moc Boot Patterns

1. Main materials needed

2. Overview of the patterns

3. Overview of the Cut Pieces

4. Overview of the Skived Pieces

5. Assembling and Sewing the Uppers

6. Creating the insole

7. Lasting the Uppers

8. Sole construction

Chukka Boot - Shoemaking Course

Chukka Patterns

1. Main materials needed

2. Overview of the patterns

3. Overview of the Cut Pieces

4. Overview of the Skived Pieces

5. Assembling and Sewing the Uppers

6. Lasting the Uppers

7.Creating the insole

8. Sole construction

9. Heel construction

10.Shoe last removal

11.Insole Cover Application

🥾 Monthly Shoe Patterns

MOD14-BOOTS

MOD75-LOAFER

MOD41-SANDALS

MOD77-ENGINEER BOOTS

MOD44-OXFORD

MOD73-DERBY

MOD67-Hiking Boots

MOD5-HIGH-HEELS-10CM

MOD3-Double Monk

MOD54-Toughest Boot in the World

MOD6-Sneakers

MOD66-Moc Shoes

and more,

Choose your plan

Begin your shoemaking journey today!